Dear colleagues, the production company EXZOTRON TECHNOLOGY, after long tests, is ready to present you our unique development and the company's novelty in the field of fuel filling accuracy:

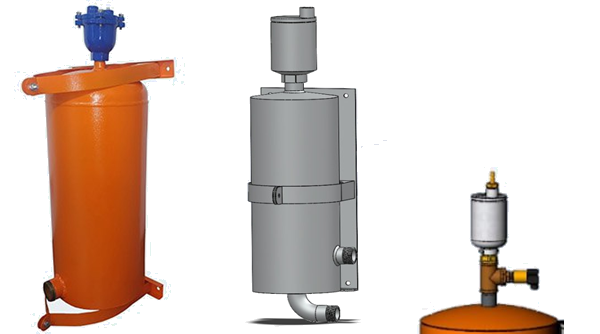

Vortex Gas Separator (EX-Air Separator DN Series)

Our development is intended for high-quality separation of foam and air in the process of fuel transfer, especially important for accounting for fuel when using: electric pumps that drive foam strongly (the problem of fuel foaming by the pump blades), if the native pump on the tanker at high speeds contributes to foaming, when a situation arises when the fuel gun, by cutting off the fuel, (automatically or by the operator) whips up the mixture, in the event of a kink in the injection hose, air intake or an increase in its length, if there are filters, valves and adapters in the pumping lines, etc. This constantly affects the quality and accuracy of fuel accounting, increasing its volume by 3-5% of the total mass of pumped fuel.

Purpose and principle of operation

This device is designed to be installed in front of diesel fuel meters to separate foam and air. In the process of pumping diesel fuel through fuel lines, various devices, such as a fuel pump, fine and coarse filters, as well as other mechanisms, the effect of fuel foaming occurs from pressure drops. This device is designed to remove both foam and air from the fuel. The presence of foam and air impairs the accuracy of fuel metering, which is completely excluded when using this device. Recommended for installation on pumping units (stations for calibration of fuel tanks), fuel tankers, fuel dispensers, as well as on the return fuel lines of diesel engines in front of fuel meters. The device allows to increase the accuracy of any fuel metering point by at least 2-3 times the actual error, as well as completely eliminate the human factor influencing the equipment error. When using our vortex gas separator, at our company's calibration stations, the dose filling repeatability is at the level of 1 - 2 grams per 10 liters at a flow of 60 liters per minute instead of 20-30 grams without using a gas separator.

Specifications:

| Maximum working pressure | 16 bar |

| Types of connections (threaded) | 25 / 40 / 50 mm |

| Product weigh | 10/11/19 kg |

| Height with air valve | 720 / 720 / 910 mm |

| Tank diameter | 150 / 150 / 300 mm |

| Width with fixing | 200 / 200 / 350 mm |

| Working environment | Diesel fuel |

| Pressure loss, % | 10 %. |

Equipment:

Gas separator -1 pc.

Mount - -1 pc.

Air valve - 1 pc.

Tube - -1 pc.

Fitting 10mm. - 1 PC.

Clamp 32 - 35mm - 2 pcs.

Fitting 25 / 40 / 50mm - 2 pcs.

Gas separator blocking automation

In order to optimize the accuracy of filling fuel, as well as completely eliminate the human factor to exclude the possibility of air pumping through the meter, EXZOTRON TRCHNOLOGY has developed a system for automatically blocking the fuel supply when the maximum amount of air appears in the gas separator tank. Automation of blocking the pumping of a large volume of air through the gas separator is carried out by installing an additional pressure sensor between the gas separator tank and the air valve (see figure).

To block the delivery of fuel, when air enters in a high concentration, the following equipment is required:

• Pressure sensor (connected to the Galileosky device)

• Galileosky device (GPS / GLONASS terminal)

• Special Exotron algorithm (when the pressure in the gas separator tank drops below the set rate, the shut-off valve closes at the meter outlet)

The Vortex Gas Separator (EX-Air Separator of the DN series) is recommended both for installation and for additional retrofitting of any existing fuel transfer units, modernization of fuel dispensers, fuel tank calibration stations and mobile tankers, in order to increase the level of fuel transfer accuracy, and as well as the exclusion of the possibility of air entering the fuel meter when the ATZ tank is empty.