1. Reliable measurement: Our sensor allows you to accurately determine the operating time of the engine under load, eliminating the possibility of idling. This ensures honest payroll and fuel savings.

2. Universal solution: Due to the possibility of mounting in any position and ease of connection, the sensor is suitable for all types of motors, including special equipment where there is no access to the CAN bus or to the W terminal.

3. Resource savings: Reducing idle time by 30% allows you to significantly reduce fuel consumption, which makes our sensor not only an efficient, but also a cost-effective solution.

Advantages over analogues:

there is no interference with the electrics, so there is no risk of messing up anything

it does not work on the principle of "hot / cold", but builds a detailed schedule

simplified calibration

it is known exactly where and how to mount, and how to receive data

simplicity and reliability

affordable price

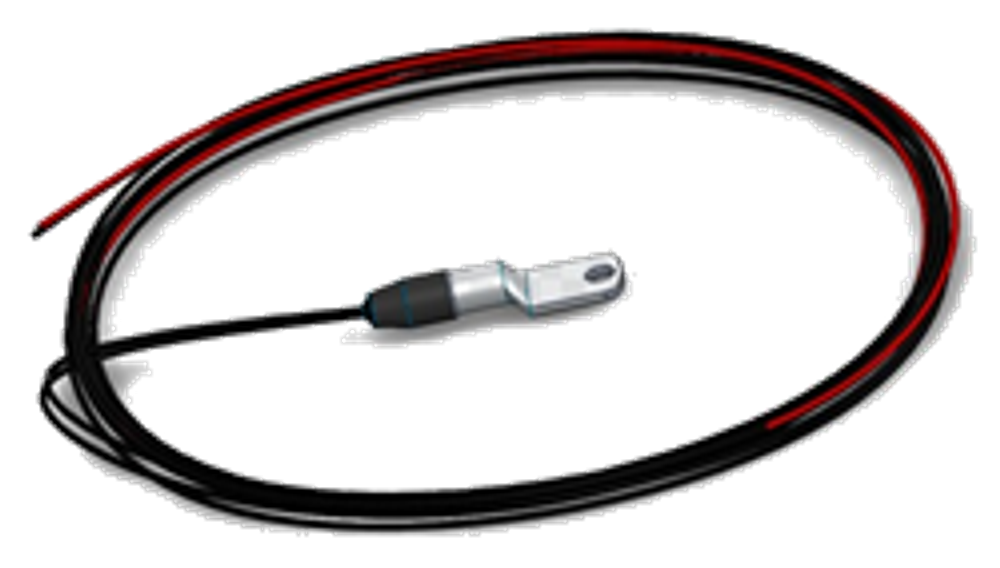

The purpose of the vibration sensor is to take readings from those internal combustion engines where it is impossible to remove the rpm via the CAN bus or by electric means. For example, the old charging generators had a W terminal, which is not present on modern ones. This is especially true for imported special equipment (various rollers, excavators, loaders).

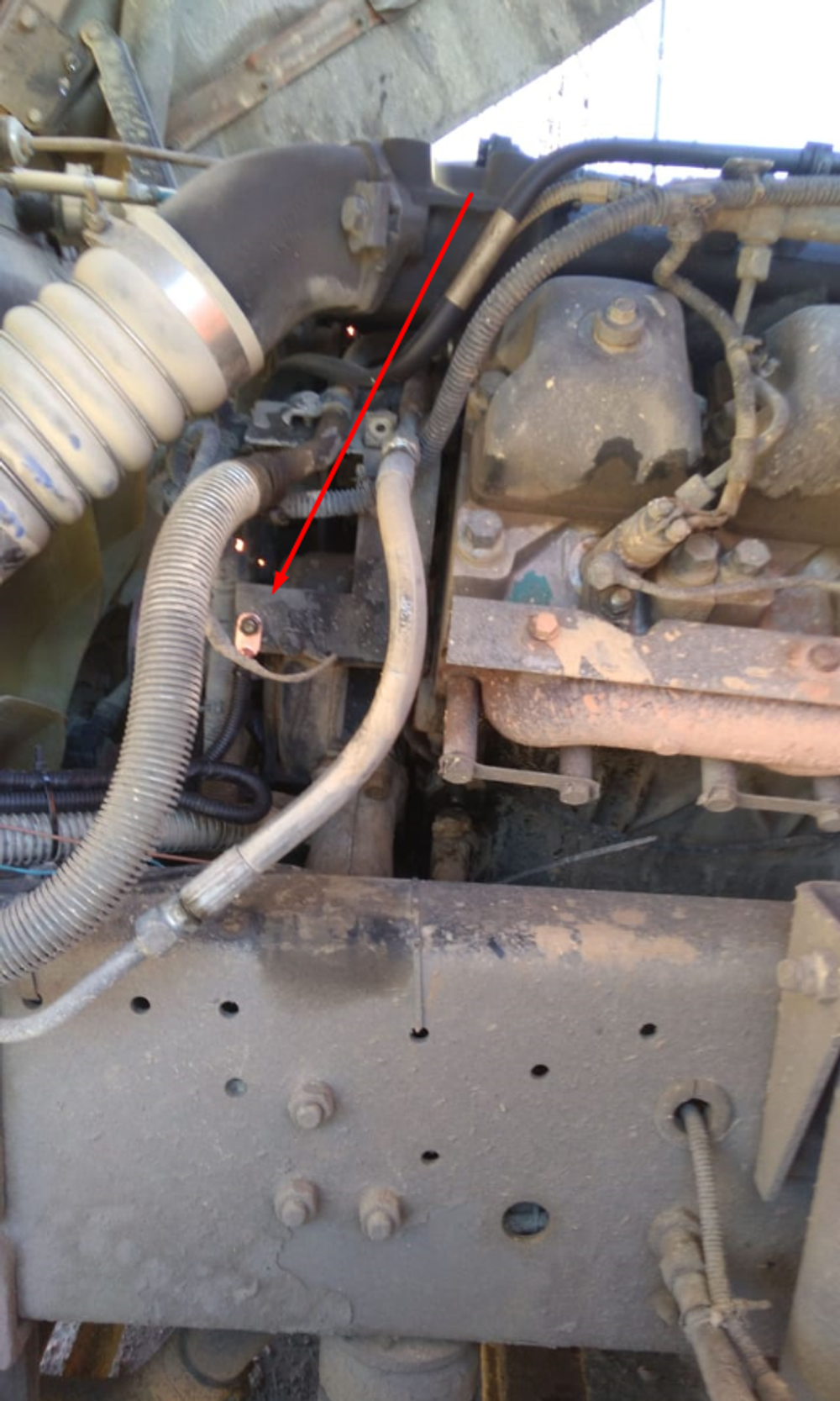

The sensor is mounted on the engine in an upright position, and at the output we receive pulses from the vibrations of the engine. Any installation engineer can handle such a sensor and the result is guaranteed on any engine.

Connection method to the tracker: The sensor has a pulse output dry contact. It is connected to the counting input of the device, which is configured as a frequency input.